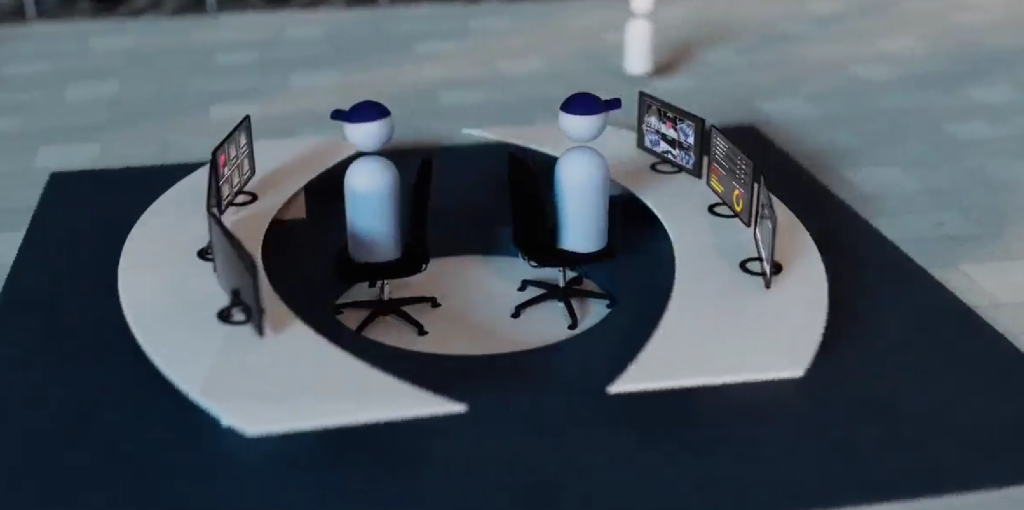

What You Need to Know Before You Build a Control Room!

How to Build a Professional Control Room

A control room is the most important room in your facility; it’s where daily decision-making affects corporate goals and the return on plant assets. A well-designed control room solution, whether it’s a new build or upgrade, total or partial, is your assurance of safer, more alert operators, more attentive monitoring, quicker and more rational responses, and higher productivity.

In this article, I will share some of the main parameters to consider when building a professional control room, based on best practices and industry standards.

Video Wall Solutions

A video wall is a large display that consists of multiple monitors or projectors that are tiled together to form a single, seamless image. Video walls are used to display information relevant to your daily operations or needed in the event of a crisis to keep everyone on the same page.

Some of the factors to consider when choosing a video wall solution are:

- Size: The video wall should be large enough to be visible from any position in the control room but not too large to cause eye strain or distraction.

- Resolution: The video wall should have a high resolution to ensure the clarity and readability of the displayed information.

- Brightness: The video wall should have a sufficient brightness level to overcome ambient light and glare.

- Contrast: The video wall should have a high contrast ratio to enhance the visibility of details and colors.

- Viewing angle: The video wall should have a wide viewing angle to ensure consistent image quality across the entire display area.

- Refresh rate: The video wall should have a high refresh rate to avoid flickering and motion blur.

- Reliability: The video wall should have a low failure rate and a long lifespan to ensure uninterrupted operation.

- Maintenance: The video wall should be easy to maintain and repair, with minimal downtime and cost.

Professional Furniture

The furniture in the control room should be ergonomic, modular, space-saving, and adaptable to the needs of the operators. Some of the features of professional furniture are:

- Adjustable height: The furniture should allow the operators to adjust their sitting or standing posture according to their preference and comfort.

- Adjustable tilt: The furniture should allow the operators to tilt their monitors or keyboards to optimize their viewing angle and reduce glare.

- Adjustable depth: The furniture should allow the operators to adjust the distance between their monitors and keyboards to suit their arm length and reach.

- Cable management: The furniture should have a built-in cable management system to hide and organize the wires and cables of the equipment.

- Storage: The furniture should have enough storage space for the operators to keep their personal belongings and documents.

- Mobility: The furniture should have wheels or casters to enable easy movement and reconfiguration of the workstations.

Suitable Interior Design

The interior design of the control room should create a comfortable, pleasant, and stimulating environment for the operators. Some of the aspects of interior design are:

- Color: The color scheme of the control room should be harmonious and soothing, avoiding bright or contrasting colors that may cause eye fatigue or distraction. Neutral colors such as gray, beige, or white are recommended for walls, ceilings, and floors. Accent colors such as blue, green, or yellow can be used for furniture, accessories, or signage.

- Lighting: The lighting of the control room should be adequate and adjustable, providing both general illumination and task lighting. Natural light should be used as much as possible, but filtered through blinds or curtains to avoid glare or heat. Artificial light should be dimmable and controllable, using LED or fluorescent lamps that have a high color rendering index (CRI) and a low color temperature (CCT).

- Acoustics: The acoustics of the control room should be controlled and optimized, reducing noise levels and reverberation. Sound-absorbing materials such as carpets, curtains, or panels can be used to dampen noise from outside sources or equipment. Sound-masking systems can be used to generate white noise or ambient sounds that mask unwanted noises and enhance speech intelligibility.

- Ventilation: The ventilation of the control room should be sufficient and efficient, providing fresh air and maintaining a comfortable temperature and humidity level. Air conditioning systems should be designed to avoid drafts, noise, or vibrations. Air filters should be used to remove dust, pollen, or other contaminants from the air.

Infrastructure Routes and Cables

The infrastructure routes and cables of the control room should be planned and installed in a safe, secure, and organized manner. Some of the guidelines for infrastructure routes and cables are:

- Location: The infrastructure routes and cables should be located away from potential sources of interference, damage, or fire, such as high-voltage lines, heat sources, or flammable materials. They should also be accessible for maintenance and inspection, but not exposed to unauthorized access or tampering.

- Protection: The infrastructure routes and cables should be protected from mechanical, electrical, or environmental hazards, such as abrasion, cuts, short circuits, or moisture. They should be enclosed in conduits, ducts, or trays that are made of fire-resistant and corrosion-resistant materials. They should also be labeled and color-coded according to their function and destination.

- Segregation: The infrastructure routes and cables should be segregated according to their type and voltage level, avoiding cross-talk or interference between different signals or systems. They should also be separated from other utilities such as water pipes, gas pipes, or drainage pipes that may cause leakage or flooding.

- Redundancy: The infrastructure routes and cables should have redundancy and backup options, ensuring that the control room can continue to operate in the event of a single point of failure or a partial outage. They should also have switches, breakers, or fuses that can isolate or restore the power supply or the communication network as needed.

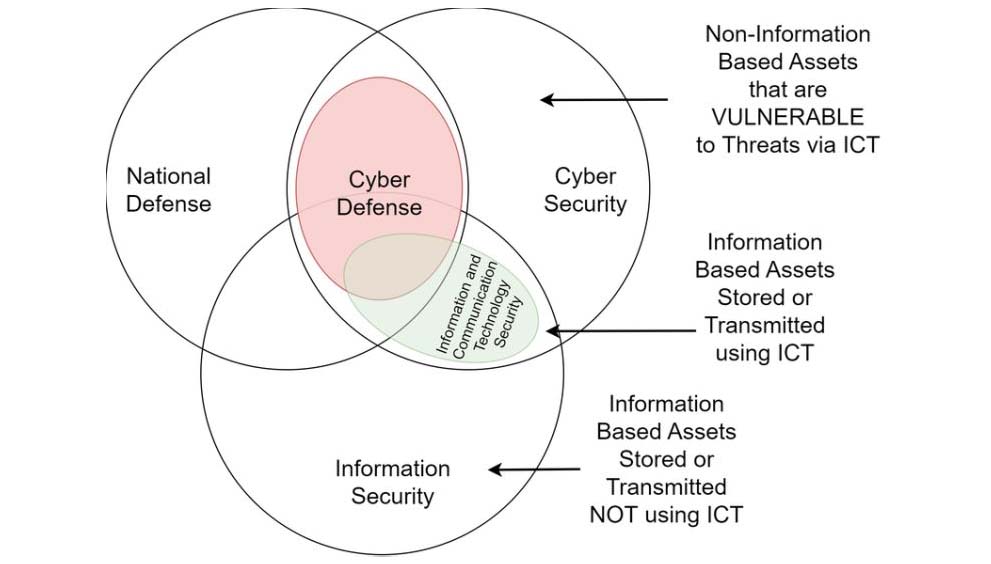

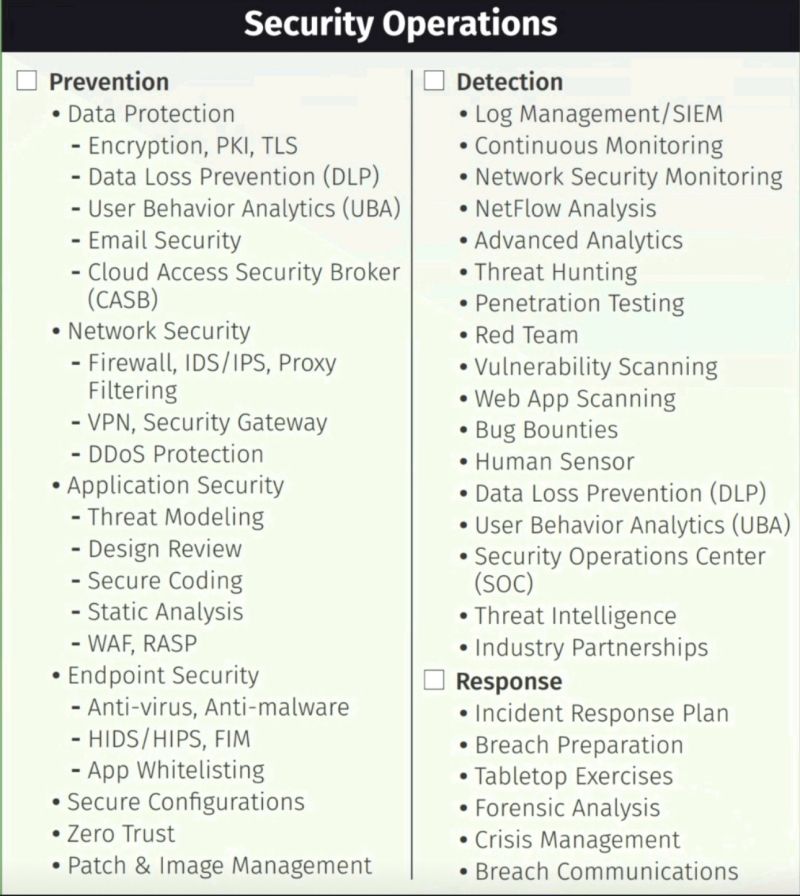

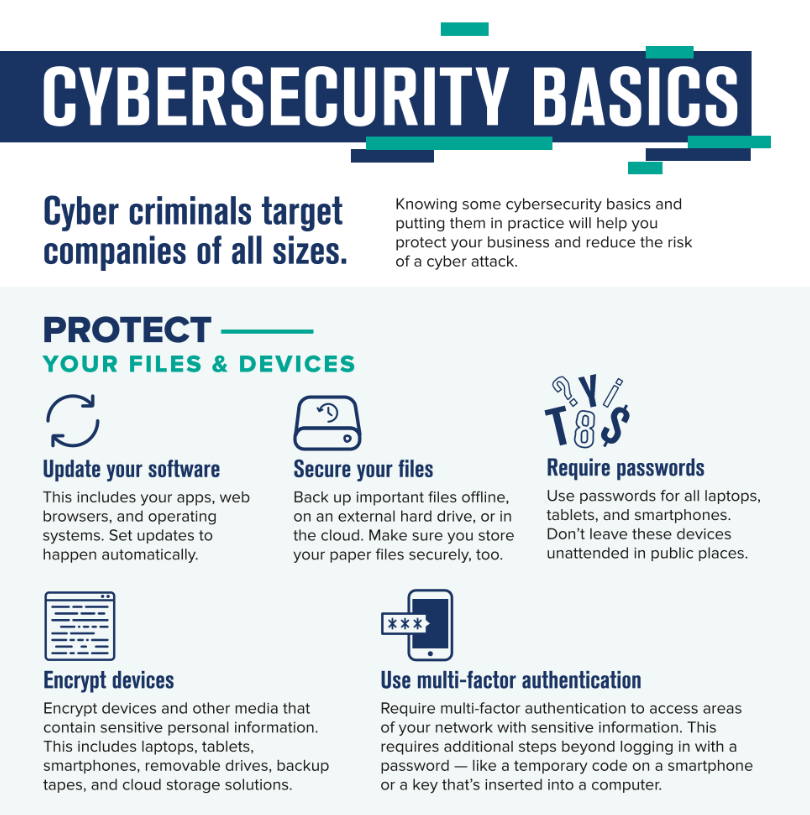

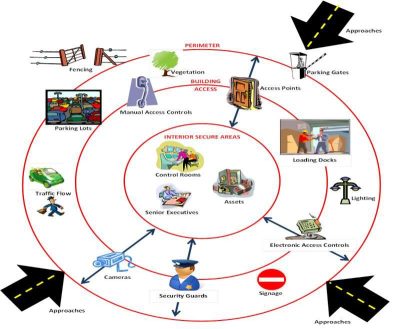

Physical Security Systems

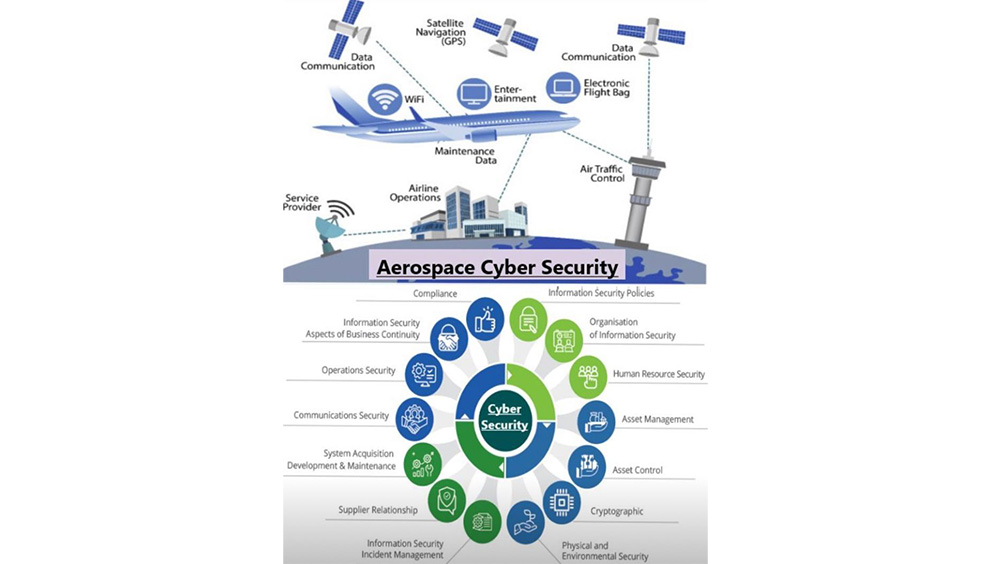

The physical security systems of the control room should prevent unauthorized entry, theft, or sabotage of the equipment or information. Some of the components of physical security systems are:

- Access control: The access control system should restrict the entry of personnel to the control room based on their identity, role, and authorization level. It should use biometric, card-based, or password-based authentication methods that are reliable and secure. It should also record and monitor the access history and activity of each user.

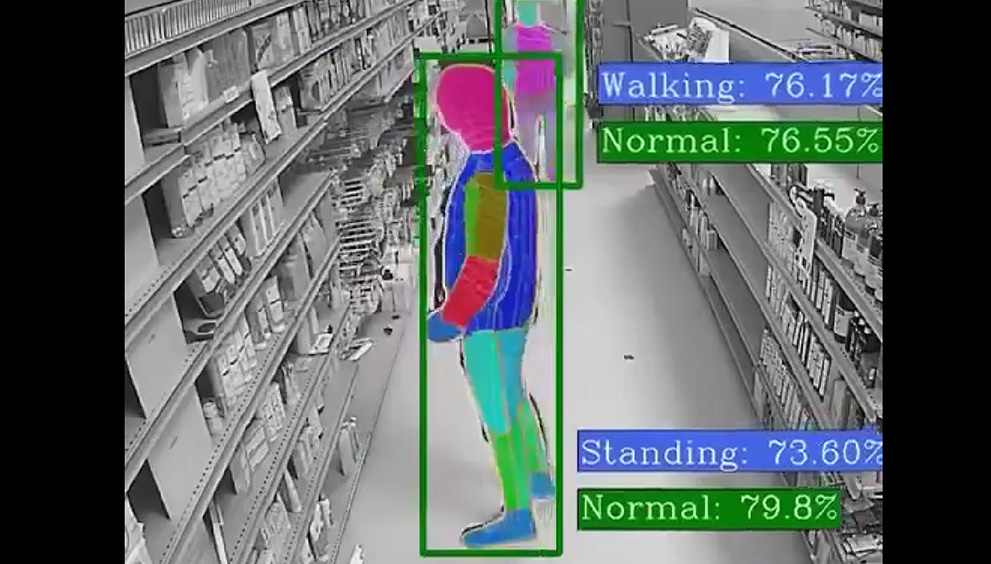

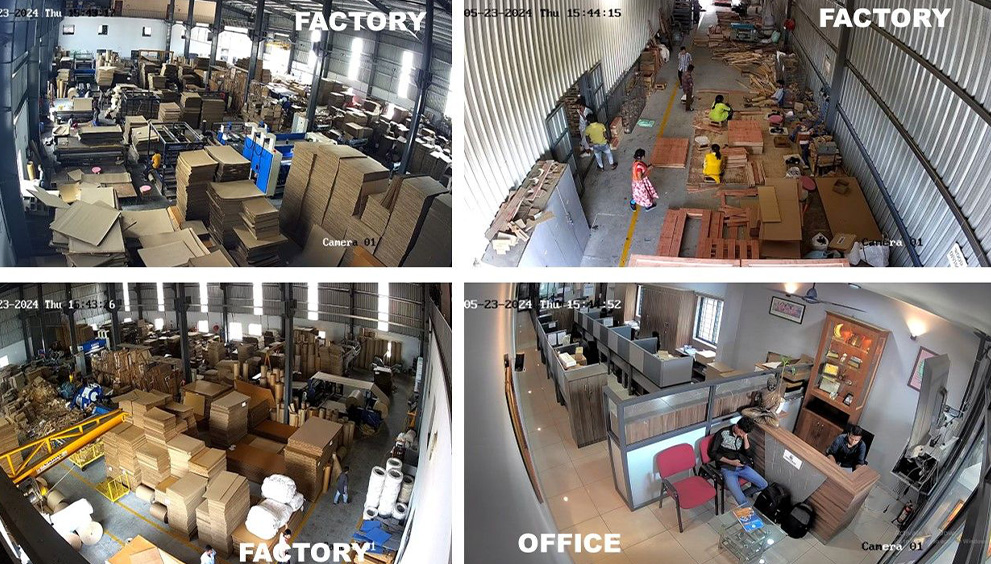

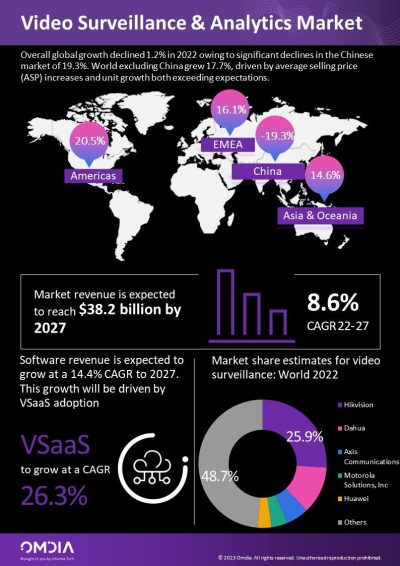

- Surveillance: The surveillance system should monitor and record the activities and events in and around the control room using cameras, sensors, or alarms. It should provide real-time video feeds and alerts to the operators or the security staff in case of any suspicious or abnormal situations. It should also store and back up the recorded data for future analysis or evidence.

- Intrusion detection: The intrusion detection system should detect and deter any attempts to breach the perimeter or the interior of the control room using physical or cyber means. It should use motion detectors, door contacts, glass break sensors, or firewalls that can trigger alarms or countermeasures in the event of any intrusion attempts. It should also notify and report the incidents to the relevant authorities.

Associated Services Sub-Rooms

The associated services Sub-rooms are the auxiliary rooms that support the operation and maintenance of the control room. Some of the examples of associated service sub-rooms are:

- UPS room: The UPS (uninterruptible power supply) room houses the devices that provide backup power to the control room in case of a power outage or a power quality issue. It consists of batteries, inverters, chargers, and controllers that can switch from the main power source to the backup power source seamlessly and automatically.

- Server room: The server room houses the servers, routers, switches, and other devices that store and process the data and information for the control room. It consists of racks, cabinets, cables, and cooling systems that ensure optimal performance and reliability of the devices.

- Generator room: The generator room houses the generators that provide emergency power to the control room in case of a prolonged power outage or a major disaster. It consists of engines, alternators, fuel tanks, and exhaust systems that can generate electricity from diesel, gas, or other fuels.

- HVAC room: The HVAC (heating, ventilation, and air conditioning) room houses the equipment that regulates the temperature, humidity, and air quality of the control room. It consists of chillers, boilers, fans, ducts, and filters that can heat, cool, and circulate the air in the control room.

I hope this post has given you some insights into how to build a professional control room that meets your operational needs and safety standards. If you have any questions or comments, please feel free to contact me.

Resources:

- https://marketscale.com/industries/pro-av/7-best-practices-for-optimizing-your-control-room-operations/

- https://new.abb.com/control-rooms/control-room-design

- https://www.hse.gov.uk/comah/sragtech/techmeascontrol.htm

- https://guide.nepsi.eu/wp-content/uploads/2020/09/2.1.3-Design-of-control-rooms.pdf

Member Login

Member Login