Think Risk Management! Think Aastrid Lifesciences Pvt. Ltd.!

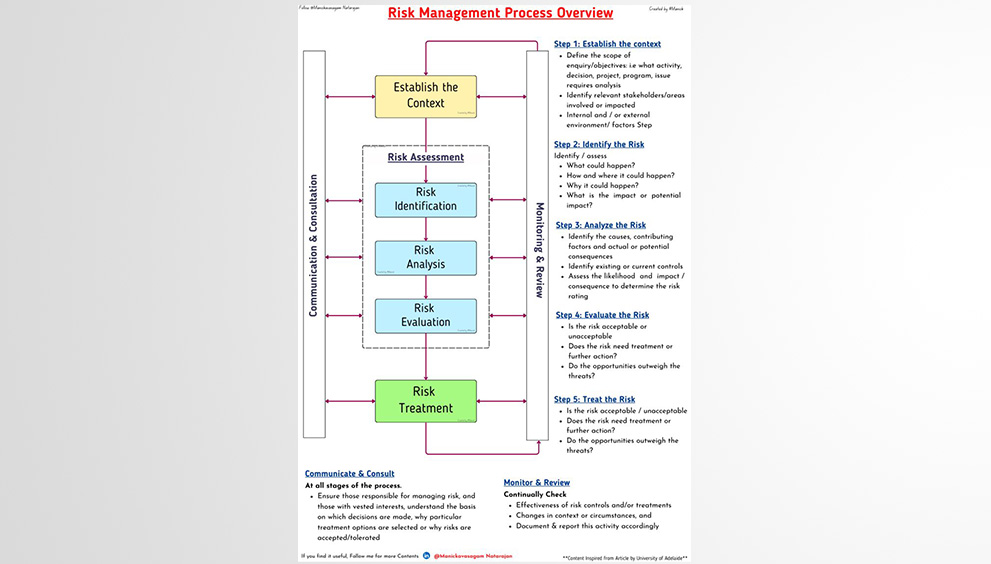

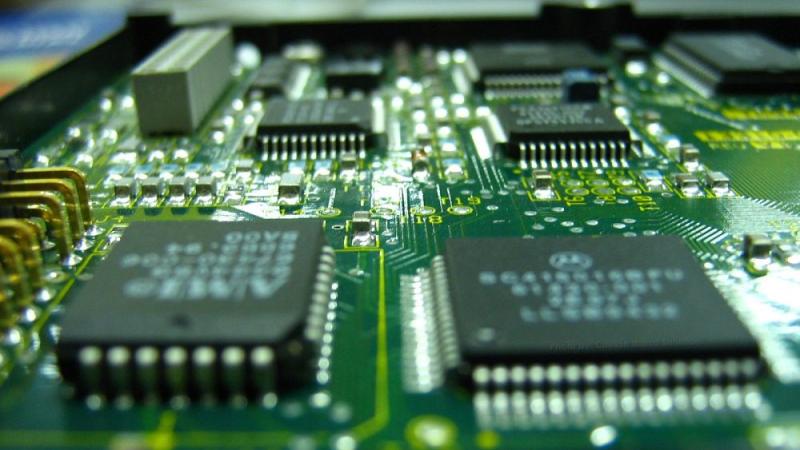

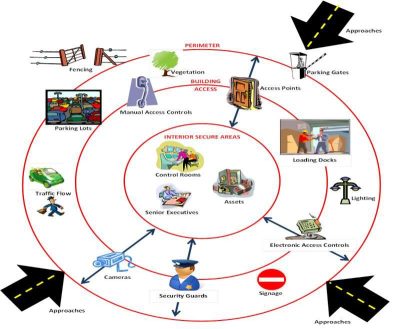

We at Aastrid believe that, “Risk Management” in chemical manufacturing operations is paramount due to the inherent hazards associated with handling chemicals. It involves identifying, assessing, and mitigating potential risks to ensure the safety of workers, protect the environment, and safeguard assets.

Here’s a brief overview of the importance and key aspects of risk management in chemical manufacturing:

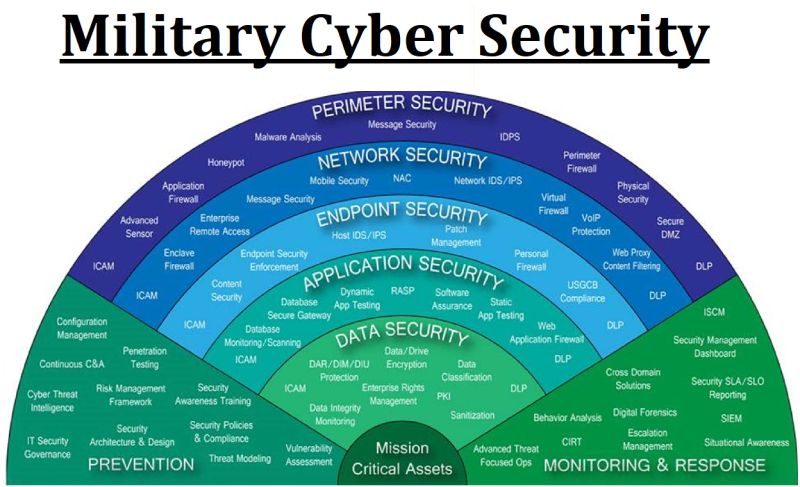

1. Identification of Hazards: The first step in risk management is identifying potential hazards associated with chemical manufacturing processes, including exposure to toxic substances, fire, explosion, and environmental contamination.

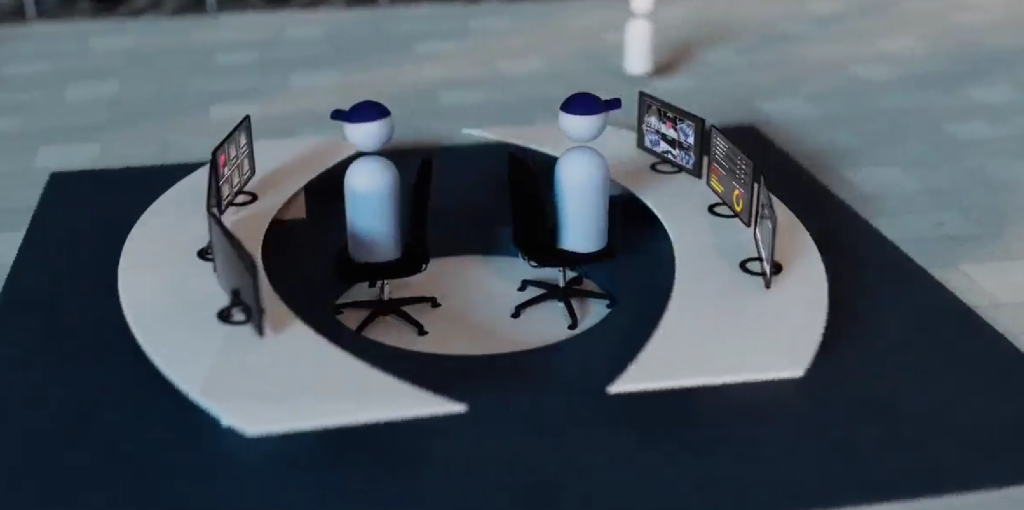

2. Risk Assessment: Once hazards are identified, risk assessment techniques are employed to evaluate the likelihood and consequences of potential incidents. This involves analysing factors such as process conditions, equipment reliability, human factors, and external threats.

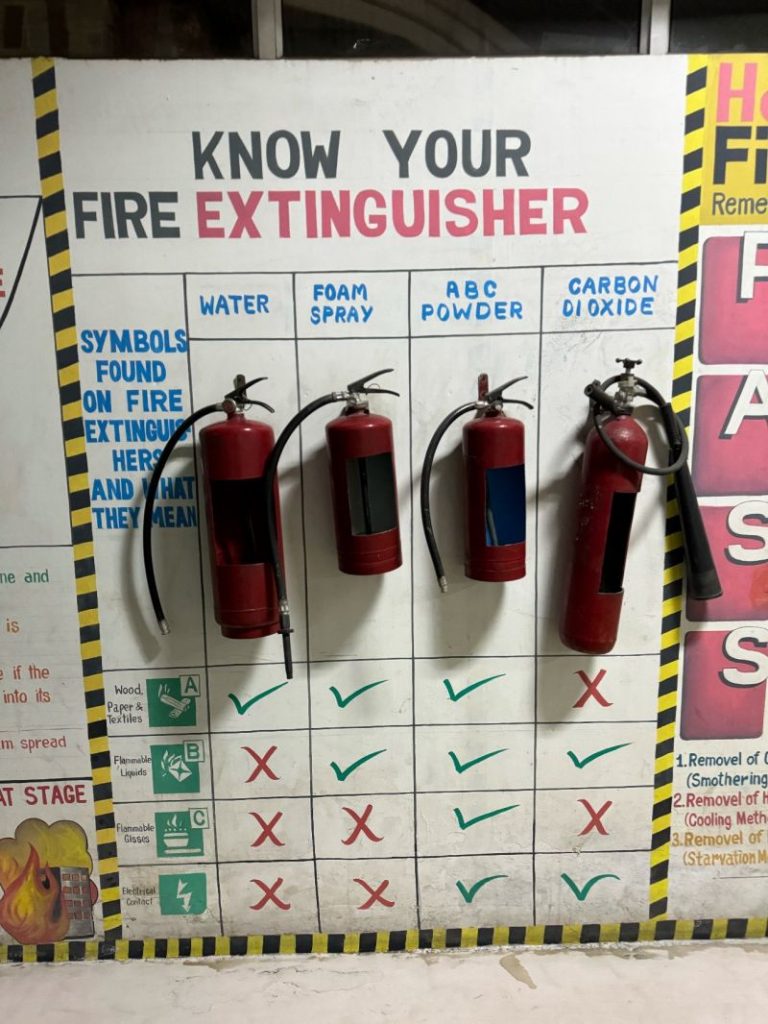

3. Mitigation Strategies: Based on the risk assessment, mitigation strategies are implemented to reduce or eliminate identified risks. This may involve engineering controls, such as containment systems and ventilation, administrative controls, such as standard operating procedures and training programs, and personal protective equipment.

4. Emergency Preparedness: Despite mitigation efforts, there is always a possibility of accidents or unforeseen events. Therefore, effective emergency preparedness plans are essential to respond promptly and effectively to incidents, minimize their impact, and protect personnel, the community, and the environment.

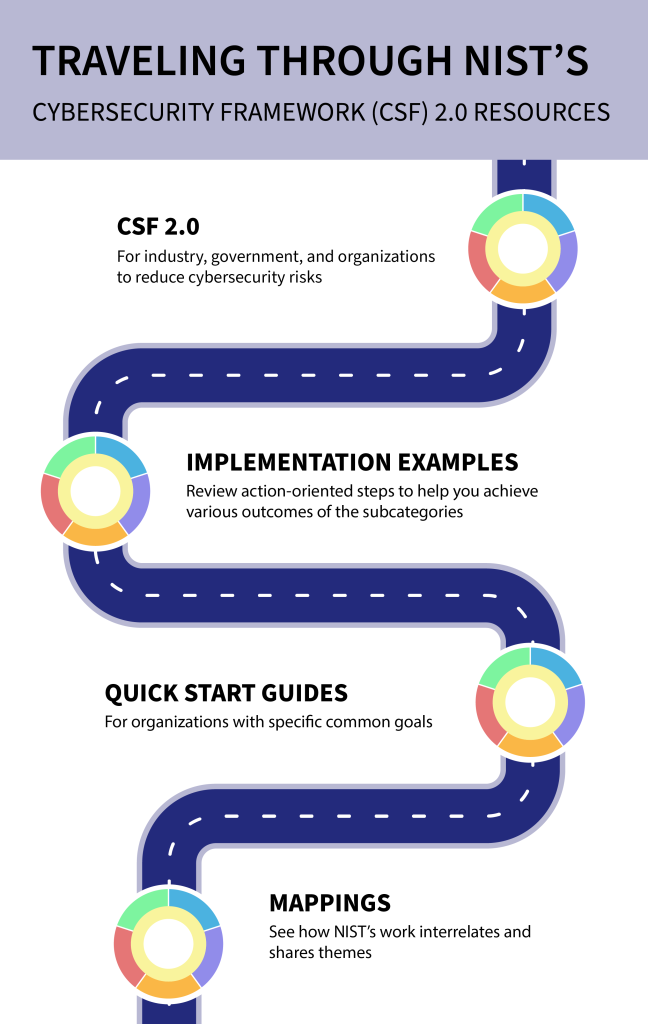

5. Regulatory Compliance: Compliance with regulations and standards governing chemical manufacturing operations is a critical aspect of risk management. Companies must adhere to applicable laws, permits, and industry guidelines to ensure the safe handling, storage, and disposal of chemicals.

6. Continuous Improvement: Risk management is an ongoing process that requires continuous monitoring, review, and improvement. Companies should regularly update risk assessments, incorporate lessons learned from incidents and near misses, and implement corrective actions to enhance safety performance.

7. Cultural and Organizational Factors: Creating a safety culture where all employees are engaged, empowered, and committed to safety is essential for effective risk management. Strong leadership, clear communication, and employee involvement are key drivers of a safety culture within chemical manufacturing organizations.

hashtag#aastridlifesciences

hashtag#pharmaintermediates

hashtag#specialitychemicals

hashtag#apiintermediates

hashtag#researchanddevelopment

hashtag#innovation

hashtag#CDMO

hashtag#CRO

hashtag#riskmanagement

Member Login

Member Login